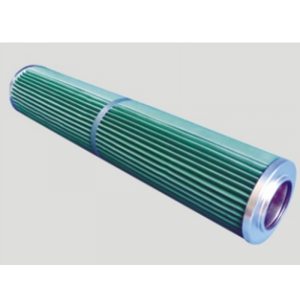

Isihluzo se-sintered mesh sisihluzo esiqinileyo esiphakathi sintered ukusuka kwiileya ezininzi zocingo olulukiweyo olunobukhulu obuthile bepore kunye nedayamitha yocingo.Inkqubo ye-sintering idibanisa iingcingo kwindawo yoqhagamshelwano, idala isakhiwo esomeleleyo, esomeleleyo kunye nesingenako.Olu lwakhiwo lwahlukileyo lwenza into yokucoca i-sintered mesh ibenentsebenzo ephezulu yokuhluza, ukungeneka kunye namandla omatshini.

Izinto zokucoca umnatha we-Sintered zibonelela ngezisombululo ezibalaseleyo zokuhluza kwizicelo ezahlukeneyo ezinje ngokucoca igesi, ukuhluzwa kolwelo kunye nokwahlulwa kolwelo oluqinileyo.Into yokucoca inokucoca ukungcola kunye namaqhekeza amancinci njenge-1 micron ububanzi.Ukongezelela, isakhiwo esisisiseko siqinisekisa ukusabalalisa ngokulinganayo inkqubo yokucoca, okubangelwa ukusebenza kakuhle kokucoca kunye nokuhla koxinzelelo oluphantsi.

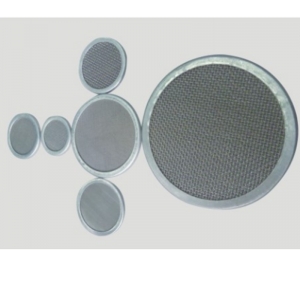

Izinto zokucoca umnatha we-Sintered ziyilwe ngokwemigangatho eyahlukeneyo kunye nobukhulu besiko, iimilo kunye namabakala okucoca.Unokukhetha phakathi kokulinganisa okuqhelekileyo ukusuka kwi-1μm ukuya kwi-300μm kunye nemilinganiselo yokucoca ngokupheleleyo ukusuka kwi-0.5μm ukuya kwi-200μm.Iindibaniso ezahlukeneyo ze-pore kunye needayamitha zocingo kwizinto zokucoca i-sintered mesh zibonelela ngokuguquguquka kokucoca okusebenzayo kunye nokusebenzayo kwiinkqubo ezahlukeneyo zamashishini.

Izinto zokucoca isinyithi esine-sintered mesh zenziwe ngezinto ezikumgangatho ophezulu ezimelana nomhlwa njengentsimbi engatyiwa, iHastelloy, kunye ne-titanium alloys.Amandla kunye nokuqina kwezinto ezibangela ubomi obude kunye neendleko eziphantsi zokugcinwa kunezinye imidiya yokucoca.Izinto zokucoca umnatha we-Sintered zikwalula kakhulu ukuzicoca kwaye zifuna ukutshintshwa rhoqo, ukunciphisa ixesha lokungasebenzi kunye nokwandisa imveliso.

Izinto zokucoca umnatha wesinyithi we-Sintered ziyaguquguquka kwaye zinokulungiswa ngokwezidingo ezithile zokucoca kwimizi-mveliso.Inokufakwa kwiindawo ezahlukeneyo zokucoca, iqinisekisa ukuba isebenza kwiinkqubo ezahlukeneyo zokuhluza.Isixhobo sokucoca sinokusebenza njengenkxaso yezinto ezahlukeneyo zokucoca, ukubonelela umgangatho ophezulu wokukhusela.

Iimpawu zemveliso

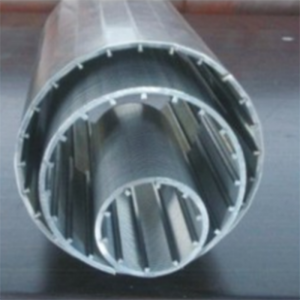

1) Ipleyiti yemesh eqhelekileyo ene-sintered ibandakanya umaleko okhuselayo, umaleko wolawulo oluchanekileyo, umaleko wokusasazwa kunye nomgangatho wokomeleza.

2) Ukungena kakuhle, amandla aphezulu, ukuxhathisa okuqinileyo kwe-corrosion, kulula ukuyicoca kunye nokuchasana nokucoceka, akukho lula ukonakalisa, akukho nto ivaliweyo.

Iinkcukacha zobugcisa

1) Izinto eziphathekayo: 1Cr18Ni9T1, 316, 316L

2)Ukuchaneka kohluzo:2~60µm

3) Ukusetyenziswa kobushushu: -20 ~ 600℃

4) Ubuninzi boxinzelelo oluphezulu: 3.0MPa

5) Inombolo yomaleko: 2-7layer

6) Ubungakanani bunokwenziwa ngokweemfuno zabathengi